The company

Our technical office is open from Monday to Friday from 8 am to 6 pm by:

Phone +49 (0) 90 71 / 58 65-0

Fax +49 (0) 90 71 / 65 02

info@kuehbeck.de

Our technical office is open from Monday to Friday from 8 am to 6 pm by:

Phone +49 (0) 90 71 / 58 65-0

Fax +49 (0) 90 71 / 65 02

info@kuehbeck.de

Our technical office is open from Monday to Friday from 8 am to 6 pm by:

Phone +49 (0) 90 71 / 58 65-0

Fax +49 (0) 90 71 / 65 02

info@kuehbeck.de

Alois Kühbeck GmbH –

Strong in the Market

All-round Service

Historie

Five Decades of Experience

Our production area has now reached a size of more than 7.000 m².

We manufacture exclusively at our company site in the Swabian town of Dillingen on the Danube and can thus guarantee a high standard of quality as well as preserve jobs in Germany as a business location.

Over 50 years of experience, a target-oriented know-how and forward-looking action secure the future of our company.

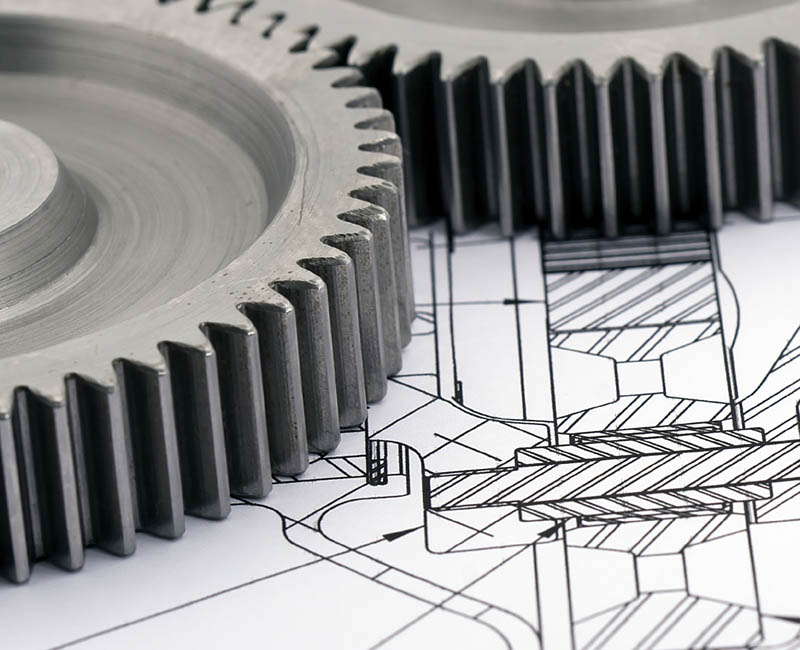

Precision from Tradition

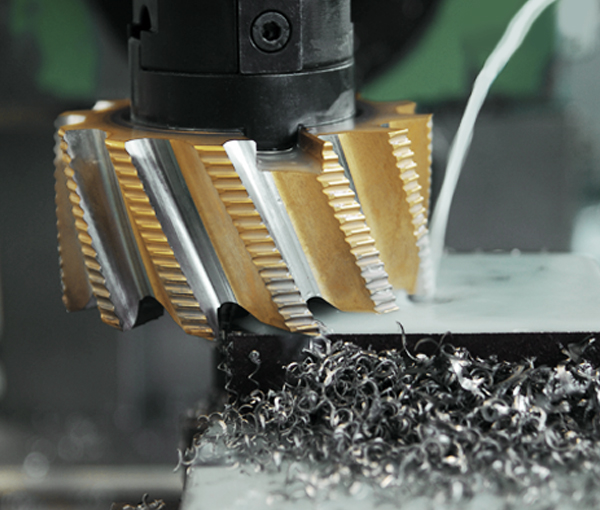

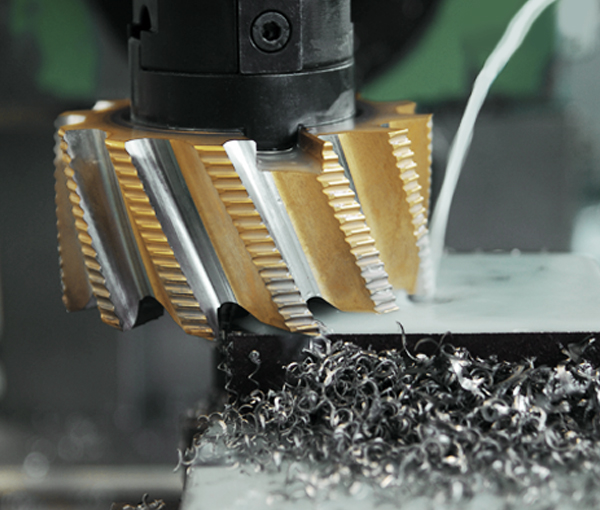

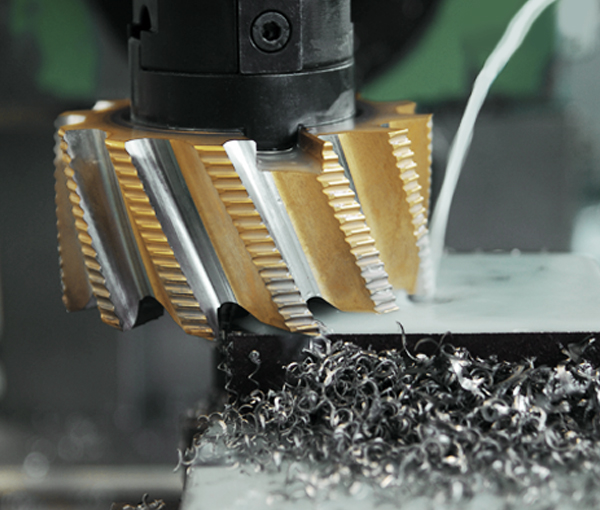

We offer a wide range of services in the areas of milling, drilling, turning and boring mill turning and are able to respond quickly and efficiently to individual customer requirements.

Through the continuous further training of our employees, we guarantee the latest state of the art technology. Years of experience, quality and flexibility make us a renowned specialist for the production of precision turned and milled parts.

Engineering

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Our Machinery Park

An essential basis for our success is a large, versatile and state-of-the-art machinery park, which comprises, among other things, machining centres, CNC-directed turning and milling machines, the latest generation of grinding machines as well as our own induction hardening plant. We have a comprehensive range of quality steels and non-ferrous metals constantly in stock.

Therefore, we dispose of many different processing and production possibilities and great flexibility with short reaction times.

- Drilling and milling machines

flatbed, gear hobbing, horizontal and vertical CNC milling machines - Turning machines

i.a. carousel and CNC turning machines - Induction hardening plants

- Grinding machines

centre, centreless, internal and flat grinding machines - Vertical shaping machine

- Various sawing machines

- Welding machines

- Clamping devices

rotary tables, tilting tables, rotary tilting tables, indexing devices and magnetic plates - Coordinate measuring machine

Coordinate measuring machine